![]()

Phone +420 541 143 246, Fax +420 541 142 224, E-mail: heatlab@fme.vutbr.cz, www.heatlab.cz

Hydraulic Descaling

Hydraulic descaling is used for removing oxides from steel surface. Experimental work is concentrated on the study of descaling in relation to heat transfer and the quality of removing the scales from the surface. The test bench for the measurements of impact forces is available.

Experimental Equipment

The key measurements are done on linear test bench. A test plate is heated and the test bench accelerate plate running through the spray chamber. The major studied parameters are: water pressure, inclination angle, type of nozzle, distance of the nozzle from surface, effects in the overlapping area.

Heat Transfer Test

Heat transfer tests use an instrumented test plate where temperature is recorded while running under the descaling jet. Heat transfer coefficient distribution is obtained as a function of spray parameters.

Procedure of the experiment:

• An electric furnace (heater) heats the test plate to an initial temperature of the experiment.

• The plunger water pump is switched on and the pressure is adjusted.

• A driving mechanism moves the test plate under the spray. After recovering the temperature field in the plate, the movement of the plate under the spray is repeated.

• The sensors measure the temperature at a depth of 1 mm from the cooled surface.

• The positions of the test plate and the sensors (in the direction of movement) are recorded together with the temperature values.

|

|

| Temperature history at sensor position, pressure 5 and 45 MPa |

Averaged HTC in dependence on water pressure |

|

Test plate equipped by sensors, heat transfer test |

Quality Test

The quality tests use the test plates with defined layer of oxides. Final surface quality after hydraulics impact is studied.

|

|

| Test plate with oxide layer, quality test |

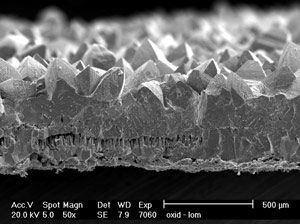

Electron microscope photo of primary scale

|

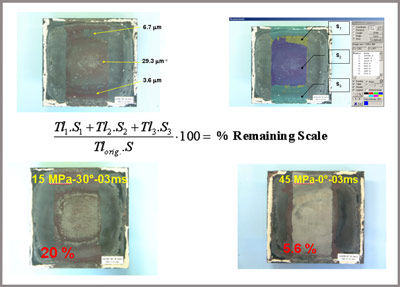

Thickness of scale after descaling is measured by a special sensor or by electron microscope. Image analysis is used for evaluation of percantage of remaining scale.

|

| Evaluation of percentage of remaining scale using image analysis. Two cases of spraying parameters - pressure 15/45 MPa, inclination angle 30/0 deg, velocity 3 m/s. |

Impact Pressure Measurement

Impact pressure distribution is a basic parameter which can be used for nozzle characterization. Special test bench was developed in Heat Transfer and Fluid Flow laboratory to measure these parameters.

|

| Impact pressure measurement |

Special Cases

|

|

Special cases can be studied. The above photo shows the descaling test with sub-cooled central part of a test plate. |

Great effort is focused on the study of defects related to the overlapping area of descaling nozzles. Overlapping can cause thermal strips and quality defects appeared on the surface. |